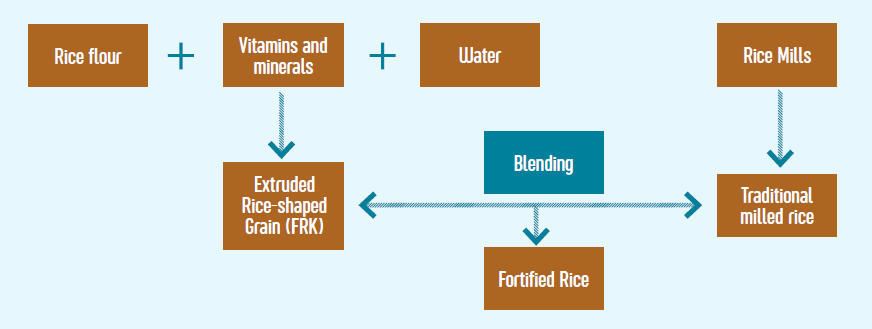

Rice can be made more nutritious by adding vitamins, minerals and other nutrients to replenish micronutrients lost in the milling process and reinforce its nutritional value. Fortified rice can be adjusted based on the nutritional needs and can made to resemble the different rice varieties.

There are different methods to make rice more nutritious post-harvest:

- Dusting– this is where rice kernels are dusted with a micronutrient powder, relying on an electrostatic force to bind the dry powder to the surface of the grain. Fortified rice produced by dusting cannot be washed or cooked in excess of water.

- Coating– a method that involves the use of a fortificant mix and ingredients such as wax or gum to ‘fix’ the micronutrient layer being sprayed onto rice. The produced fortified kernels are blended with regular rice, typically at 0.5 – 2% ratio.

- Hot or warm extrusion– hot extrusion is considered the most robust method of rice fortification, supported by extensive evidence base to have a positive impact on micronutrient deficiencies. Broken rice grains are ground into rice flour, then mixed with water and the required nutrients to produce a dough. The fortified dough is then passed through an extruder to produce the fortified kernels, which are then blended with regular rice typically at 0.5-2% ratio. The temperature at which the extrusion takes place determines if we speak of hot or warm extrusion and has an influence on the rice starch gelatinization and thus firmness of the produced fortified kernels.